Welcome to Concept Engineers

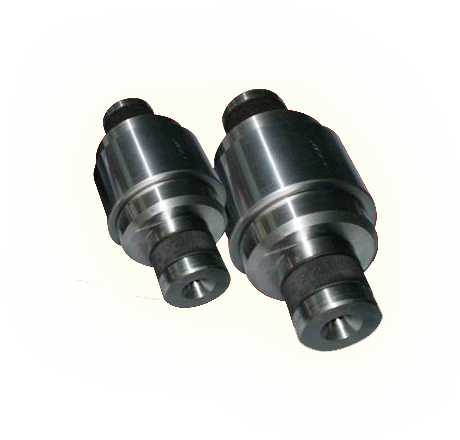

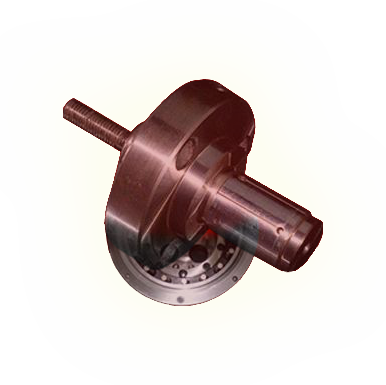

Hydraulic Expanding Mandrels / Arbors by Concept Engineers Concept Hydraulic expanding mandrels / Arbors is one of its kind ' Work holding technology’.

Are market leaders in the field, spanning over an extended period of over thirty one years and continuing with excellent reputation and growth, with client support from both domestic as well as international market. The technology involved in ‘Hydraulic expanding mandrels / arbors’ is adapted from the famous ‘ Pascal's Law/ principle of hydrostatic transmission of pressure.

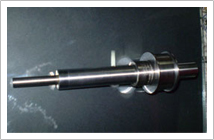

The mandrel / arbor consists of a ported body with a radial cavity over which is embraced a thin steel tube overlapping the annular cavity which is fused to form a single entity. The enclosed cavity is filled with a hydraulic medium which when energized tends to compress the hydraulic medium to multiply by many folds, there by exerting a radial load, forcing the overlapping tube to expand itself outwards uniformly to locate / clamp a part, enabling to perform various metal removing, finishing ,gauging operations.

The actuation / energizing can be attained by either manual/external force or directly by a power pack. The construction of the Hydraulic expanding mandrel / arbor is such that, it has the ability to attain very high accuracy of less then 0.003 microns. Also, in most cases the mandrel blends to extend itself to become a part of the machine, thereby transferring the attainable accuracy of the machine directly on to the part.

Design flexibility ensures it to adapt itself in performing almost all kinds of machining operations such as,

- Dynamic balancing.

- Gear honing.

- Gear grinding.

- Gear shaving.

- Gear hobbing.

- Cylindrical grinding.

- Milling.

- Turning.

- Fixture location.

- Inspection / gauging.

Read More..

Features & Benifits

- Sophisticated, State-of-the-art Engineering Designs

- In compliance with industry standards and specifications

- High quality and precision

- Uncompromising thoroughness

- Easy implementation and maintenance

- Provide optimum solution to weak links in machining chain

- Solve most difficult clamping problems

- Reduce rejections to a minimum

- Reduce cost

- No requirement of additional skill

- Adopted to perform any machining operation